At YPP, we derive our “We can do it” service approach from inherited age-old experience. Structural design, printing, finishing, die-cutting, folding, gluing, assembling, shipping — they all matter. But what matters most is that we take great care of our customers.

Our facilities are where quick turns meet world-class quality and service. At YPP, 21st century technology lives side-by-side with centuries old artisanal finishes. We deliver results and make your brand’s vision a reality.

Our design team develops innovative structural designs that stand apart considering all aspects of packaging designs including shelf appeal, functionality & product protection. We operate with the very latest design tools, software and expertise turning your ideas into reality with the latest CAD plotting table offering you exceptional samples in any shape, size and material.

Our environmentally friendly ‘computer direct to plate’ system enables us to transfer digital information accurately, assuring not only optimal sharpness and superior detailing but also longer lasting plates on the printing presses. Every job is checked by our color pilot control system to ensure your prints remain true to your corporate colors, whether it be a one-off job or year on year print runs.

We offer full service commercial print. With our variety of presses from Heidelberg, we have the flexibility to manage all your printing needs in one place. Our production turnaround times are impressive to say the least, and this was made possible when we invested in high specification state-of-the-art KBA Rapida 105 press, featuring seven printing units and coater. During production, automated loading and unloading coupled with in-line inspection eliminates the need for human intervention and speeds up the production process, providing further opportunity to check colour accuracy against your brand guidelines. Our machines produce dry prints, further speeding up the process.

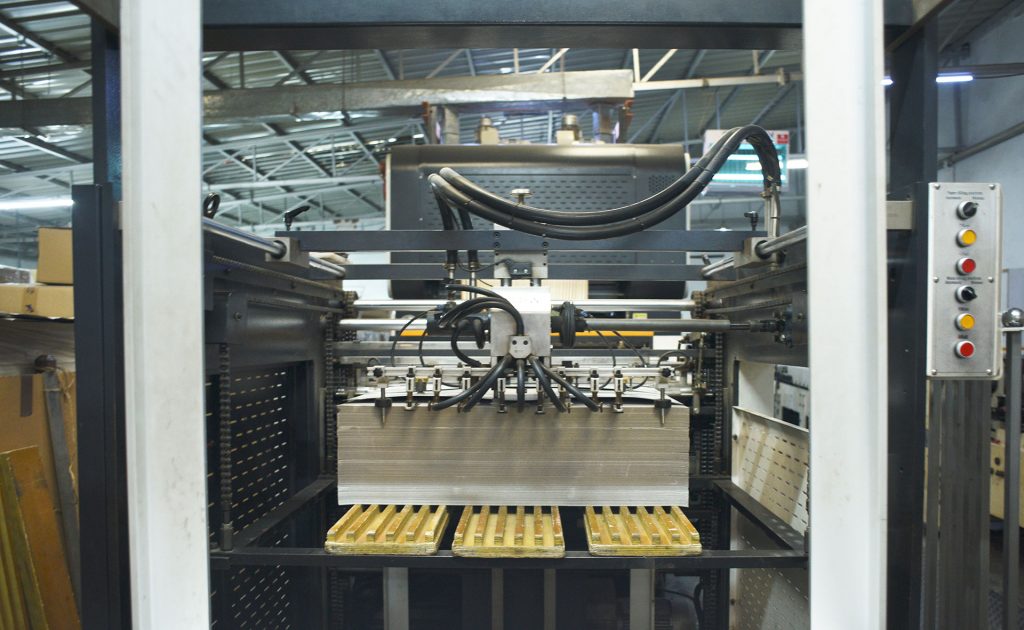

Die cutting & creasing are a demanding process that requires great skills. Our precision die cutting capabilities allow us to offer you some very intricate carton designs by combining automation, accuracy & our team of highly experienced craftsman.

Our auto die-cutters, the YOCO 106 & YOCO 106E, are equipped with ground-breaking technology to maximize productivity and reduce waste. With these machines we are able to die-cut virtually any material to shape with a bespoke tool designed in-house on our very own CAD system.

Our precise folding and gluing machines allow us to produce a broad spectrum of sophisticated and premium folding cartons in a highly economical way. With superb processing quality and short make-ready times we produce consistently high-quality cartons with impressive turnaround times.

The PAKTEK 650 and DGM 1100 are the two multi-purpose folder gluers of choice, handling a wide selection of substrates and styles. These machine guarantee quality assurance and are able to handle the most difficult of shapes, folds and materials with ease.

At YPP, we have dedicated quality assurance department at all its sites which upholds rigorous quality standards, working closely with customer to provide them the support they require. We source raw materials from certified suppliers only.

Proper recording of technical parameters is done at each stage enabling us to produce quality goods. Our quality assurance department ensures products are thoroughly inspected to uncover defects before dispatching the production.